Green Woodworking Hand Tools

Green Wood:

When people say green wood then they are not referring to the wood that is green in color as indicated by the words. In fact, green wood is referred to the freshly cut wet unseasoned wood which didn’t had a chance to be evaporated and therefore contains lot of water.

In any softwood, all the moisture present in wood is in the form of free water in the lumen or bound water within the cell walls of the cells. Removal of bound water causes shrinkage in wood. This removal of water is naturally done by evaporation or manually done in large kilns.

Wood is still regarded as green wood for at least one year if it is left unprocessed in the form of logs. Green wood is usually cut into planks and air dried for one year so that its water content is reduced to less than 21 percent so that substantial amount of shrinkage take place. The other way is to dry the wood in kilns so that moisture content is reduced to less than 10 to 12 percent.

Working with green wood is based on splitting rather than the sawing technique and is done usually along the grain of the wood.

Why Green Wood?

- The basic advantage of working with green wood is that it can be split easily and uniformly.

- Green is soft due to the presence of moisture and this makes it easier to work with hand tools and is capable of creating very strong and stable furniture if the type of wood used is properly understood.

- Some species of green wood are processed and assembled green because these types of wood split less when nailed green.

- Moisture in green wood is used for the making of some really tight fitted green woodworking joints which utilizes the shrinkage property of green wood.

- Working with green wood can be also done in open environment and even on the site where trees are directly cut. Thus, gives the opportunity for the woodworkers to work in fresh environment as usage of power tools is hardly required.

- Green wood is generally regarded as environment friendly as it uses the coppicing technique for obtaining the wood. In this practice, trees are cut down at the base or stool before they reach maturity so that they can grow multiple times before they reach maturity.

Hand tools for green wood:

Woodworking with green wood generally involves the usage of hand tools only as the wood is still soft. You can make great furniture or timber frames using green wood if you know completely about your wood and have some experience of woodworking. It is little bit difficult to handle and work with the hand tools if you are a novice as it is quite slippery and wet.

The hand tools generally used for green wood are:

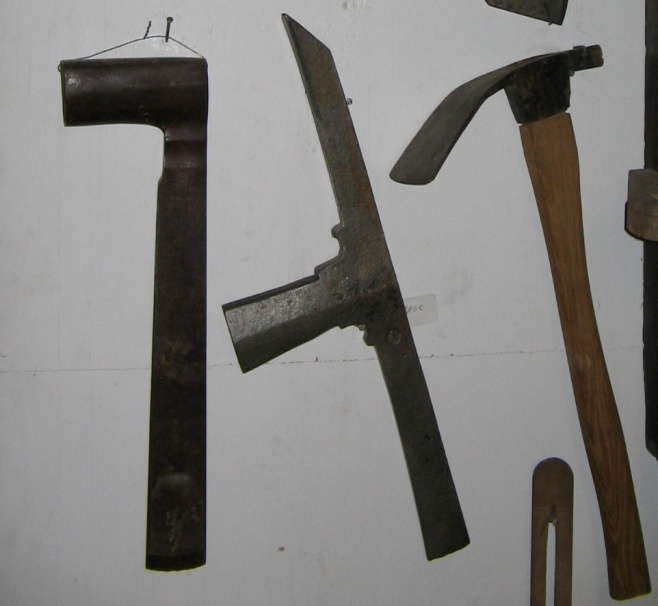

- Adze: An adze or Adz tool is a heavy tool curved at right angle to the handle used for cutting and shaping wood. This is one of the basic tools which was extensively used in stone era in the form of handheld stone shaped into a blade. As the time passed, it was slightly modified and is still being used with metal head and wooden handle.

- Bark Spud: A bark spud is also known as peeling iron or peeling bar. As suggested by the name itself, this is used for peeling the bark from the felled trees or logs.

- Bill Hook: A bill hook is a bigger version of knife and a smaller version of an axe. It is used for cutting woody parts of plants like the side shoots from a branch or logs. It is also used as a gardening tool for hedging and cutting branches.

- Broad Axe: A broad axe is a big or broad headed axe and is used for plank hewing. It is available in two types. One is flat from side and beveled from the other side, and thus named as side axe or basilled edge broad axe. The other type is beveled from both the sides and therefore known as the double side Broad Axe and is often used for making joints.

- Cleaving Axe: A cleaving axe or cleaver is used for splitting green wood length wise. Green wood is split lengthwise in order to reduce the shrinkage factor drastically.

A Draw Knife: A drawknife is also known as draw shave or shaving knife and is used for shaping the wood by removing the shavings out of the wood. It consists of a long blade in the middle with handles attached to both the ends.

- Froe: A froe (frow) is an L-shaped tool which is also known as shaking axe or paling knife. It is used for splitting the wood by hammering the handle of the froe and thereby pushing the sharp edge of the tool into the wood along the grain and then twisting the handle.

Hacking Knife: A hacking knife also known as side knife is a heavy version of a knife or the light version of a hatchet which is used for splitting timber. It has single sided straight edge just like a small cleaver. It has a very strong steel handle usually hit by steel hammer.

- Slick: A slick is a large chisel having a broad, heavy and slightly curved blade and a thin and long handle.

- Twybil: A twybil is a tool used for cutting mortises and smaller pieces for doors and windows out of green wood. It looks like a T-shaped double edged axe with long blade and a short handle. It can be used in two ways. The axe like blade fitted parallel to the handle can be used for cutting and the other crossway edge can be used for prying and levering purpose.

- Pole Lathe: A pole lathe is also known as a spring pole lathe works best for the freshly felled green wood. It uses the elasticity within a long pole as a return spring for a treadle. When the treadle is pressed, the cord wrapped around the wood or billet is turned or pulled back.Cutting is performed during the down stroke of the treadle. A modern bungee cord replacement can operate in smaller space but here also the lathe rotate in both the directions and cutting is done only during down stroke.

These are the basic hand tools used for processing green wood. You can choose to work with Hand held Planer blades tools that suit your working style and requirements.